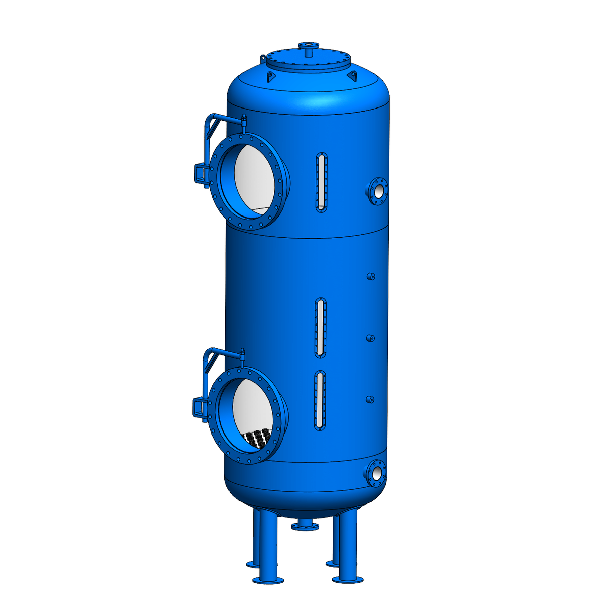

Ion Exchanger Pressure Vessel

UNITEX pressure filter manufacturer offers user-friendly and ecological Vessels technologies that helps to remove a wide variety of contaminants from water. Ion exchange water demineralization equipment is used wherever these is a need for very low water conductivity, mainly in the power industry, paint industry, electroplating. Plants of this type produce demineralized water using ion exchange technology. Bed regeneration requires chemicals such as hydrochloric acid and sodium hydroxide. Post-neutralization wastewater, before discharging to the sewer, must be neutralized.

The Ion Exchangers is made of high grade P265GH steel The filter is made of high grade P265GH steel type and can be equipped with filtration system with nozzle bottom with filtration nozzles or stainless steel lateral system.

Production capabilities

We manufacture Pressure Filters made of carbon steel in diameters from DN500 to DN4000 mm. Our designers and technologists will help to adjust pressure Ion Exchanger to requirements and expectations of our customers.

Ladders and platforms to support service and maintenance of the Filters:

Work safety and easy servicing of pressure vessels is a very important issue. At UNITEX we make sure that our solutions are comfortable and safe for future users.

Corrosion Protection of the Pressure Filter

One way to help our customers is to provide high quality corrosion protection. In our professional blasting and painting cabins we carry out internal and external corrosion protection. This ensures our customers a long trouble-free use of their Ion Exchangers.

Interior coating: Ion exchangers are tanks internally protected by anti-corrosion using ebonite lining providing high resistance to chemicals, as well as a high degree of resistance to mechanical damage and abrasion of the corrosion protection. We can rubber lining with approval for contact with drinking water.

External coating: We carry out anti-corrosion protection based on epoxy-polyurethane coating systems and are performed in accordance with the DIN EN ISO12944 standard in corrosivity classes C3 to C5. The use of a high-class polyurethane topcoat provides UV resistance to the paint.